Lean

From Concept to Reality: Designing Efficient Work Cells with Simulation

Work cell design, often called cellular manufacturing or cellular layout, is a strategic approach to organizing workstations and equipment in a manufacturing environment.

Lean

Work cell design, often called cellular manufacturing or cellular layout, is a strategic approach to organizing workstations and equipment in a manufacturing environment.

Lean

In lean methodology, the concepts of Muda, Mura, and Muri are crucial for understanding inefficiencies and driving continuous improvement.

Lean

Continuous improvement and problem-solving are critical in manufacturing for maintaining competitive advantage and operational excellence.

Lean

Efficiency is a fundamental aspect of contemporary manufacturing, directly influencing industry productivity and profitability. To sustain high efficiency, businesses strive to comprehend and manage Muda, a concept deeply ingrained in lean manufacturing principles.

Lean

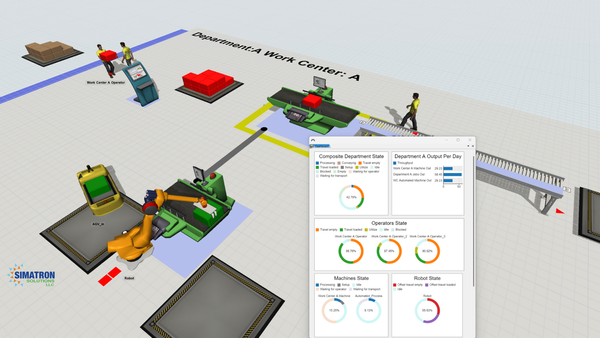

Lean manufacturing minimizes waste and optimizes productivity, revolutionizing industries worldwide. FlexSim, Simatron’s main simulation software, transforms waste elimination. This article explores how FlexSim simulation enhances lean manufacturing's potential.

Lean

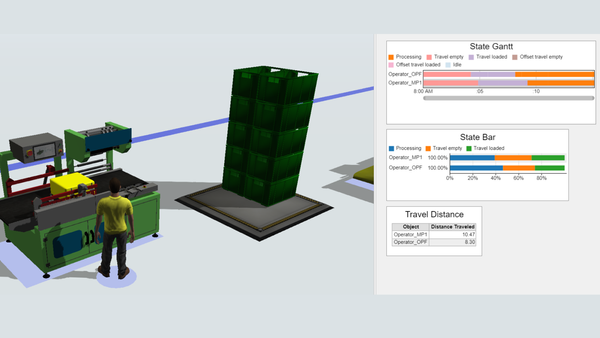

In this blog post, I will thoroughly explore how simulation, mainly using the advanced capabilities of FlexSim, plays a pivotal role in analyzing and optimizing one-piece flow within manufacturing environments.

Lean

The manufacturing industry is constantly striving for efficiency, quality, and speed. At Simatron, we have seen the benefits of combining lean thinking with advanced simulation tools like FlexSim.